Bunk beds are more than just space-saving furniture—they’re versatile solutions for modern living. Whether you’re a parent optimizing a shared bedroom, a retailer curating inventory, or a distributor seeking market insights, understanding the nuances of bunk bed styles, sizes, materials, and trends is critical.

This guide dives deep into the specifics, offering actionable advice and industry knowledge to inform your decisions.

Classification by Bunk Bed Style

To create more functionality in a limited space, the design of bunk beds has long broken through the traditional framework. They are not only a space-saving tool, but also a functional work of art for home design.

By analyzing the six mainstream styles, we can not only understand their structural differences but also master how to choose the most suitable bed type according to the usage scenario. The following in-depth analysis will help you make an accurate decision.

| Type | Minimum Room Area | Applicable Room Layout |

| Standard Bunk Bed | 8㎡ | Square small space |

| Loft Bunk Beds | 6㎡ | High-ceiling apartment |

| L-Shaped Bunk Bed | 10㎡ | Special-shaped/corner area |

| Triple Bunk Bed | 12㎡ | Ultra-high space |

| Futon Bunk Bed | 9㎡ | Multifunctional living room |

| Bunk Bed With Trundle | 8㎡ | Temporary accommodation needs |

Standard Bunk Bed

As the most basic structural form, standard bunk beds achieve space doubling through vertical stacking. Their upper and lower bunks are perfectly aligned, with an overall height of 1.5-1.8 meters, and the ladders are mostly fixed or inclined ladders.

Usually, most standard bunk beds are made of steel frames or hardwood materials, the guardrail height is generally increased to more than 15 inches, and the column spacing is reduced to 3.5 inches, which meets ASTM international safety standards. The load-bearing performance is optimized for more than 300kg.

Material Selection: North American FSC-certified pine wood has the highest cost-effectiveness, and oak wood has a 30% increase in hardness but doubles the price.

Safety Details: The height of the upper bunk guardrail must be 15cm higher than the mattress, and the step spacing must be ≤30cm.

Applicable People:

- Families with two children (safer if the age difference is more than 3 years)

- Student dormitories/summer camps

- Families with limited budgets but need long-term use

Buying Guide to Avoiding Pitfalls

- Test the shake of the bed frame: Hold both sides of the upper bunk with both hands and shake it. If the displacement exceeds 2cm, it means the structure is unstable.

- Check the hardware: Galvanized steel bolts are preferred to prevent ordinary iron screws from rusting.

- Mattress matching: It is recommended to use a thin mat with a thickness of ≤20cm for the upper bunk to prevent the guardrail from failing.

Loft Bunk Beds

The single-layer elevated structure raises the sleeping area by 1.4-1.7 meters, and the lower floor releases the entire ground space, which can be transformed into a study, storage area, or leisure corner.

Functional expansion is achieved through modular components, which are particularly suitable for small-sized apartments with a floor height of more than 2.6 meters. The vertical utilization rate is increased by 60%, which is a space optimization tool for urban singles and teenagers.

Ladder Selection Guide: Inclined ladders are more suitable for children, and vertical ladders save 15% of space but need to be matched with non-slip pedals.

Applicable People:

- Single apartment residents

- Families with children’s rooms less than 10㎡

- Teenagers who need independent study areas

Functional Expansion Module:

- Desk type: It is recommended to match an L-shaped desk with a depth of more than 60cm, and the lighting system must reach 500 lumens for reading.

- Storage type: The height of the bed bottom can be used to install a cabinet with a height of more than 1 meter, or a storage box or drawer cabinet with slide rails can be embedded in the bottom.

- Sofa type: With high-rebound sponge pads, it is more comfortable to have a seat depth of more than 50cm.

Space Optimization Tips:

- Vertical storage: Use bed posts to install magnetic hangers or foldable bookshelves.

- Safety upgrade: Use L-shaped brackets to fix the bed frame to the wall to prevent tipping

L-Shaped Bunk Bed

The L-shaped bunk bed forms an asymmetrical structure through a 90-degree staggered layout. The upper and lower bunks are spread out in an L shape along the wall, and a 1.2-1.5㎡ activity area is released in the center, creating a unique activity space while ensuring safety.

This type of bunk bed effectively adapts to unconventional room types such as triangles and trapezoids, accommodating 30% more furniture than traditional layouts, and combining parent-child interaction with spatial aesthetic value.

Structural reinforcement: Reinforced steel connectors are required at corners. It is recommended to check the mortise and tenon structure every six months for wooden models

Applicable People:

- Special-shaped apartments (such as triangular and trapezoidal rooms)

- Families that need parent-child interaction space

- Users who want to balance sleep and leisure functions

Combination Form:

- Bunk beds + desks

- Upper single bed + lower double bed (suitable for parents to accompany young children)

- Bunk bed + bay window tatami

Measured Data Reference:

- In a 3m×3m room, 1.2m³ more space is released than the parallel layout

- The diameter of the corner support column must be ≥8cm (wooden) or ≥5cm (steel)

- The vertical distance from the lower bed edge to the upper bed should be ≥75cm to avoid head-on collision

Triple Bunk Bed

The triple bunk bed uses a triple vertical stacking design, with a total height of up to 2.5 meters, and requires an alternating staircase or spiral staircase system.

Each floor has a clearance of ≥80cm, and the top floor is limited to 1.6 meters. The load-bearing standard is 25% higher than that of a bunk bed. Designed for high-density accommodation scenarios such as families with three children and employee dormitories, the room height is required to be ≥2.8 meters, and professional reinforcement devices are installed.

Safety Specifications: The height of the top guardrail is ≥38cm, and it must reach the height of the mattress + 15cm. It is recommended to install a fall prevention net.

Applicable Warning: It is only recommended for people over 8 years old. Wall-fixing devices are required.

Applicable People:

- Family with three children

- Youth hostel/employee dormitory

- Loft apartment with a floor height of ≥3 meters

Stair System:

- Straight ladder: the most space-saving but difficult to climb

- Alternating ladder: each step is offset by 15°, which is ergonomic

- Spiral ladder: the best safety but occupies 0.6㎡ of ground space

Futon Bunk Bed

Futon bunk bed combines the concept of Japanese tatami and transformable furniture. The lower layer is equipped with a folding mechanical structure, which can be transformed into a sofa or double bed in seconds. When the sofa is maintained during the day, a 2.4㎡ activity area can be released.

This bed type realizes the multi-functional switching of sleeping, reception, and storage. It is especially suitable for spaces such as studio apartments and family entertainment rooms that require flexible scene switching, with a release rate of 65%.

Cushion Selection: high-density foam + independent spring composite cushion layer, thickness ≥ 20cm to ensure comfort.

Scene Suggestion: home theater room with projector, study room, and temporary guest bedroom, the preferred configuration of youth social space.

Applicable People:

- studio apartment with living room and guest bedroom

- families who need flexible social space

- Japanese style enthusiasts

Usage Scenario Example:

- Day mode: the lower layer is unfolded as a sofa, and a mobile side table is used to form a reception area.

- Night mode: the lower layer pulls out the hidden bed frame and turns into a 1.5-meter double bed in seconds.

- Easter egg function: some models have storage compartments at the bottom of the sofa

Bunk Bed With Trundle

This type of bunk bed has a drawer-type roller bed frame hidden at the bottom, which can be pulled out and unfolded three times faster than a folding bed. It uses a hidden design to dynamically adjust the number of beds and only occupies 0.2㎡ of space when stored.

It is equipped with self-lubricating bearing slides and independent spring thin pads, with a load-bearing capacity of 200kg. It mainly solves temporary accommodation needs, taking into account convenience and concealment.

Mattress Compatibility: It is recommended to use a 10-15cm thin memory foam pad to avoid wear at the folding point.

Applicable People:

- Families that frequently receive relatives and friends

- Mother and baby care needs (lower layer as a nursing bed)

- Seasonal holiday home

Slide Rail System:

- Ordinary model: nylon roller + steel rail, load-bearing 120kg

- High-end model: self-lubricating bearing + damping buffer, load-bearing 200kg

Core Parameters for Purchase:

- Bed frame gap ≤5cm to prevent pinching

- It is recommended to choose a roller mattress with independent springs to avoid long-term compression deformation

Classification by Bunk Bed Size

Bunk beds can be classified by their style or by the size of their mattresses. Bunk beds on the market have different arrangements and combinations to suit different groups of people and needs.

The arrangement and combination of mattress sizes directly affect space utilization and comfort. The following decades the hidden logic of bunk beds of different specifications through three dimensions: size parameters, adaptation scenarios, and design tips.

Twin over Twin Bunk Bed

Dimensions: Both upper and lower bunks are standard single beds (38″ x75″)

Space Occupied: Total height 1.5-1.7 meters, layer spacing ≥75cm

Single layer load bearing: 200kg for steel frame model/150kg for wooden model

Space adaptation formula:

- Minimum room size: 2.4m×2m (including ladder activity area)

- Optimal floor height: 2.4-2.6 meters

- Mattress thickness limit: upper bunk ≤20cm (effective height of guardrail must be ≥22cm)

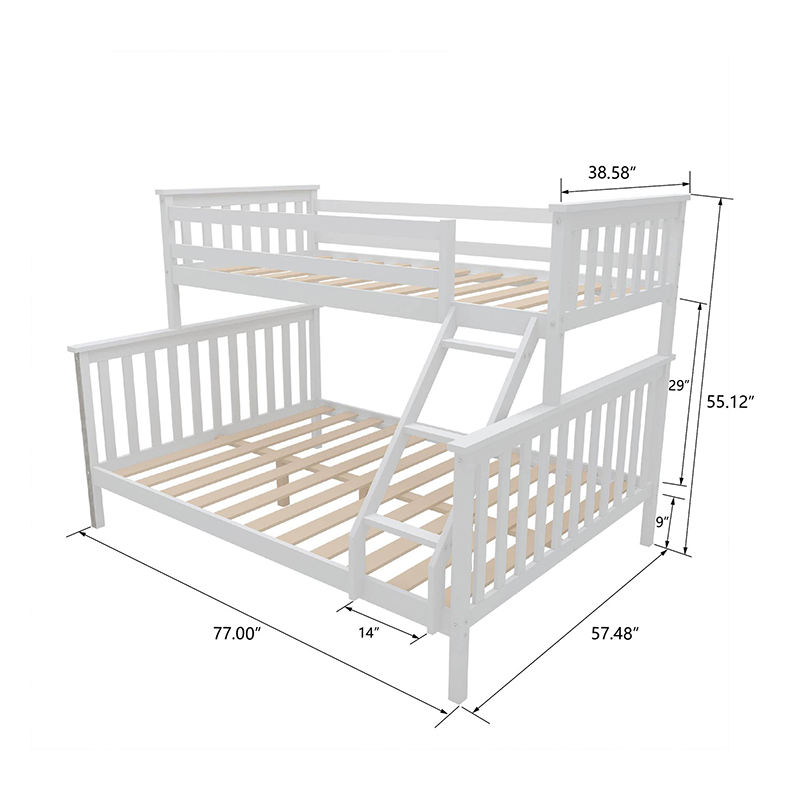

Twin over Full Bunk Bed

Dimensions: Upper bunk single bed (38″ x75″) + lower bunk double bed (54″x75″ )

Space Occupied: The offset structure makes the lower layer 38cm deeper and the overall width reaches 1.5 meters.

Floor Height Requirement: ≥40cm from the ground to the bottom of the lower bunk.

Applicable Room Type: 3m×2.5m rectangular space

Applicable People:

- The lower bunk is suitable for teenagers or adults over 12 years old

- Upper bunk weight limit 90kg (due to asymmetric load-bearing)

Full over Full Bunk Bed

Dimensions: Both upper and lower bunks are full-size beds (54″x75″)

Space Occupied: The overall area is 1.5×2m, the floor clearance is ≥85cm, and the total height exceeds 1.9 meters.

Load-bearing upgrade: 250kg/layer for steel frame model, wall anchoring is required.

Applicable Rooms: Suitable for bedrooms over 15㎡, can store 2 28-inch suitcases under the bed.

Purchase Warning:

- The tread width of the ladder must be ≥18cm (the average length of an adult’s foot is 26cm).

- Preferably choose a bedboard structure with a middle support beam to prevent the mattress from sinking.

Queen over Queen Bunk Bed

Dimensions: Both upper and lower beds are queen-size beds (60″x 80″)

Space Occupied: The overall size is 1.8×2.3 meters, and an 80cm aisle must be reserved.

Single Layer Load Bearing: Each floor can bear 300kg+, and 14G thickened steel pipes must be used.

Applicable Scenarios:

- Yacht cabin (with anti-sway locking device)

- Vacation villa (the lower floor can be converted to sofa mode)

Engineering Challenges:

- Foundation requirements: wooden floors need to be equipped with horizontal support keels.

- Transportation restrictions: special logistics is required for overall packaging dimensions exceeding 2.4m.

Materials and Durability of Bunk Beds

When choosing a bunk bed, the material is not only an aesthetic issue but also the cornerstone of safety and durability. Each material has a unique performance code, from the warmth of solid wood to the coldness of metal.

We will dismantle the physical properties of mainstream materials and analyze their different performances in terms of load-bearing, corrosion resistance, and environmental protection.

1. Solid Wood Material

Solid wood is a traditional and popular material for bunk beds. It is known for its natural aesthetics, durability, and sturdiness. Common wood types used in bunk bed manufacturing include pine, oak, and maple.

In the bunk bed market, our common raw material is pine wood because it is very cost-effective. Pine wood is light and easy to process, with a density of 450kg/m³, a moisture content of 8-12%, a load-bearing of 150kg/layer, and is prone to cracks. It is suitable for children’s beds with limited budgets. It is recommended to reinforce the mortise and tenon structure every 2 years.

Hardwoods such as oak and maple are more luxurious choices and very durable. This type of hardwood has a density of 700kg/m³ and is naturally insect-proof, but the price is 3 times that of pine wood. They can bear up to 250kg/layer and have a service life of more than 15 years.

2. Metal Material

Carbon steel is a strong and durable material made by adding carbon to iron. Carbon steel is scratch-resistant after electrostatic spraying and has a maximum load-bearing capacity of 400kg/layer. However, welding points are prone to rust, so galvanized steel is recommended for coastal areas.

Aluminum alloy is a lightweight metal made by combining aluminum with other elements such as magnesium or silicon. Aluminum does not rust easily and is very suitable for humid environments. At the same time, it is much lighter than carbon steel, so it is easier to transport and assemble.

3. Composite Material

Composite materials are man-made materials made by bonding wood fibers, particles, or veneers with adhesives. The most common types used in bunk bed manufacturing include medium-density fiberboard (MDF), plywood, and particleboard.

MDF: MDF bunk beds are made of finely ground wood fibers mixed with resin and pressed into dense panels. Their smooth surface makes them ideal for painting and laminating. However, they easily absorb moisture during use, causing expansion and warping.

Plywood: Plywood bunk beds are made of thin wood sheets laminated with alternating grain directions and bonded with strong adhesives. However, the formaldehyde emission of such products must be strictly controlled to ≤ 0.05 ppm (CARB P2 standard).

Particleboard: Particleboard bunk beds are made of wood chips, sawdust, and resin pressed into thin boards. It is the most affordable composite wood material. However, it is also the least durable and is prone to chipping, cracking, and breaking under heavy loads.

Bunk beds made of composite materials contain a lot of adhesives, which may contain formaldehyde and release VOCs. When purchasing, beware of products with excessive formaldehyde. If you are an environmentalist, such products may not be your first choice.

Bunk Bed Design Trends and Customization Options

1. Multi-Functionality & Space Optimization

As urban residents’ per capita living space continues to shrink, people tend to prefer multifunctional furniture, and the development of bunk beds has also gone beyond simple sleeping functions.

More and more modern bunk beds tend to be designed as built-in desks or workstations, while cleverly adding more drawers, shelves, and hidden compartments to enhance storage capacity.

2. Modular Configuration

Furniture manufacturers are no longer satisfied with the single form of bunk beds. They hope that bunk beds can be reconfigured and freely combined like “space building blocks”.

The bed frame, guardrails, ladders and other components adopt a unified connection system, and users can adjust the shape at any time according to their needs – today it may be a bunk bed, tomorrow it can be disassembled into two independent beds, and the day after tomorrow it can be combined into an L-shaped structure with a desk. This deformation ability provides flexibility for the ever-changing needs of families.

3. Sustainable & Eco-Friendly Materials

Sustainability has been the main driving force of the entire furniture industry for more than a decade, and people’s growing environmental awareness has promoted the innovation of manufacturing and design concepts in the furniture industry.

In bunk bed manufacturing, environmental protection concepts are penetrating from material selection to full life cycle design. Finishes with low or zero volatile organic compound (VOC) emissions are becoming the standard. Recent consumer surveys show that 60% of buyers now consider environmentally friendly finishes to be a decisive factor.

Bunk beds and other furniture products with green certification will have more competitive advantages.

What Types of Bunk Beds Can Clafbebe Offer as a Manufacturer?

Clafbebe is a manufacturer of baby furniture with more than 20 years of experience. We only produce high-quality products that meet safety standards. We offer a wide range of bunk beds.

Clafbebe’s experienced team of designers launches a variety of bunk bed products every year, which are manufactured by our independent factory and wholesaled to distributors and retailers in various regions.

We provide customized solutions for bunk beds and other products. According to your requirements, we can create products that meet your market needs, and add your logo or specific packaging to help you build your brand.

Conclusion

Whether optimizing a child’s bedroom or expanding product lines, bunk beds remain a dynamic, practical choice in modern living. Parents should prioritize guardrails and material durability, while retailers must curate diverse sizes and trending designs to meet demand.

By understanding these layers, stakeholders can make informed decisions and you’ll create spaces—or markets—that thrive.

Recommended Related Articles: